Steel structure inspection

Description

Test Range

Steel, welding materials, fastening standard parts for connection, welding balls, bolt balls, sealing plates, cone heads and sleeves, coating materials, steel structure welding engineering, welding top (stud) welding engineering, common fastener connection, high-strength bolt installation torque, parts processing size, steel component assembly size, steel component preassembly size, single-layer steel structure installation size, multi-layer and high-rise steel structure safety Installation size, steel grid structure installation size, steel structure coating thickness, etc.

Test item

Appearance, non-destructive testing, tensile test, impact test, bending test, metallographic structure, pressure equipment, chemical composition, welding materials, welding materials, weld external defects, weld internal defects, weld mechanical properties, Raw material testing, appearance quality, uniformity, adhesion, bending resistance, salt spray corrosion resistance, wear resistance, impact resistance, chemical solvent corrosion resistance, moisture and heat resistance, weather resistance, temperature change resistance, cathode stripping resistance, Ultrasonic inspection, mobile communication engineering steel tower mast structure, magnetic particle inspection, mobile communication engineering steel tower mast structure, connection fastener final twist torque detection, connection fastener strength calculation, appearance defect, anti-corrosion detection, structural perpendicularity, structural component real load, strength, stiffness, stability, etc

Detection standard

GB 50205 steel structure engineering construction quality acceptance code

NB/T 47014 Welding process evaluation of pressure equipment

JB/T 5943 General technical conditions for welding parts of construction machinery

GB/T 18226 highway traffic engineering steel components anticorrosion technical conditions

GB 50661 Welding specification for steel structures

GB 50205 steel structure engineering construction quality acceptance code

CJJ/T 235 urban bridge steel structure anti-corrosion coating engineering specification

JT/T 722 highway bridge steel structure anticorrosive coating technical conditions

About The Company

1. Established in 1985, with more than 30 years of testing experience, the first batch of third-party impartial technical inspection institutions approved by the State Administration for Market Regulation.

2. There are offices in various provinces in China, with 12 branch laboratories, which are convenient and convenient, and the testing efficiency is high.

3. Testing capabilities, including 10,000+ parameters and 4,000+ products, covering more than 3,000 items including national standards, industry standards, and international standards.

4. The testing service industry covers metal products, roads, railways, bridges, tunnels, ports, civil construction, petroleum, water conservancy, environmental engineering, etc.

Qualification Image

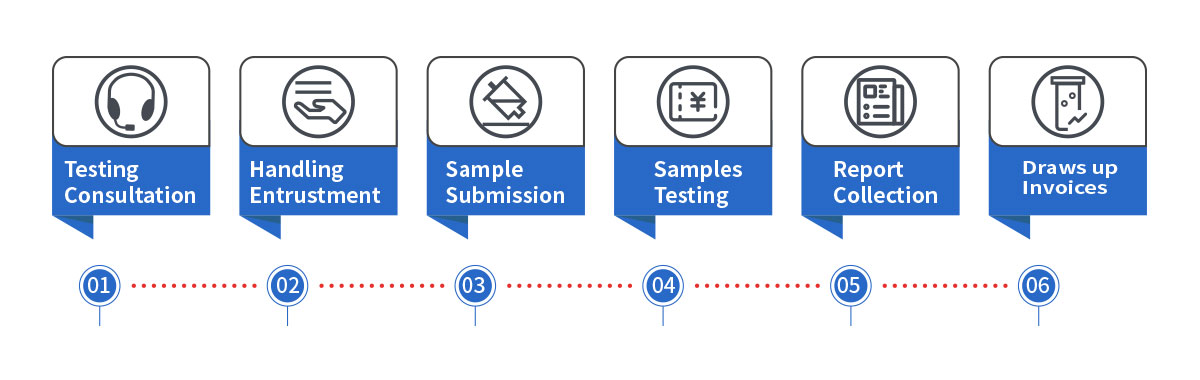

Inspection Process

Get Solution & Price Right Now!

leave your message here, we'll send you an Email immediately.

- E-mail: info@cst.ac.cn

- Add.: No.280, Guanlin Road, Luoyang, Henan, China

- Tel.: +86-4007878588